Gwesty’r Emlyn Hotel

Biomass boiler heating system helps 29-bedroom hotel provide high levels of heat to ensure guest comfort

Key Facts

Location

Carmarthenshire, Wales

Project included

- 2 x Guntamatic Powerchip 99kW boilers

- 5,000 litre thermal store

- Distribution pipework including internal connections to heat exchangers

Fuel consumption

Approximately 54 tonnes of wood pellets per annum

Fuel cost saving

40-80% wood chips or pellets, compared to heating oil

CO² saving

Approximately 55 tonnes per annum vs heating oil

RHI payments

A project of this size would gain an approximately £22,000 every year for 20 years, index linked to inflation

Total project cost

£110,000

ROI

3-4 years (combining RHI income & fuel cost saving)

Downloads

Treco project managed the installation smoothly and worked well with our in house heating engineer. We are so pleased with the system that have already purchased two further systems for another hotel.

Overview

Gwesty’r Emlyn Hotel in Carmarthenshire offers 29 stylish guest bedrooms and a function suite. The rooms have been recently refurbished to an impeccably high standard and have been individually decorated.

The challenge

With guest comfort being paramount, the hotel wanted to be able to provide ample supplies of heating and hot water at a manageable budget. They had been previously using heating oil, which had become prohibitively expensive. The owners wanted to replace the ageing oil boiler with a modern, high efficiency biomass boiler system and approached Treco.

Our custom solution

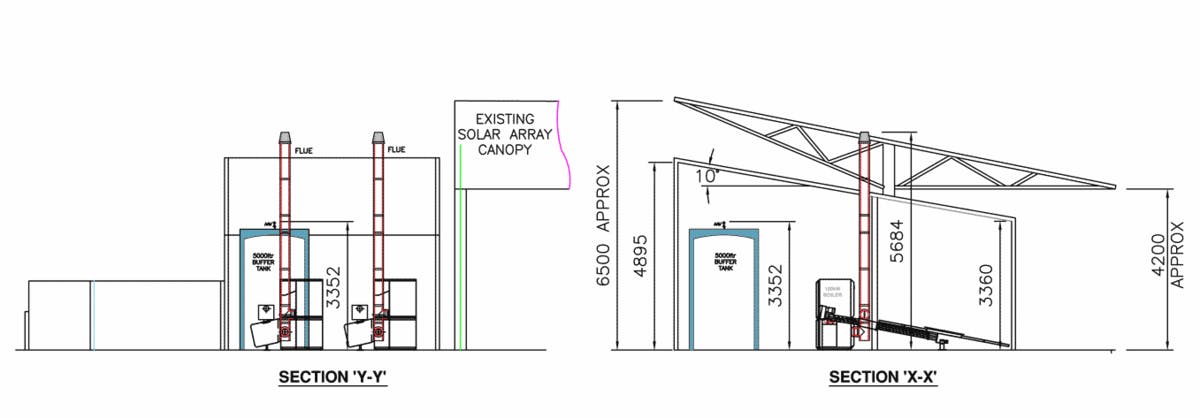

The client was responsible for the construction of the boiler house, fuel store and all downstream works. Treco installed and commissioned the biomass boiler, working with the client’s heating engineer to connect to the current system.

- Two top-of-the-range 99kW Guntamatic Powerchip biomass boilers in cascade

- Biomass boiler linked to existing heating and hot water system

- 5,000 litre thermal store

- 3.5m agitator and 3.5m auger to enable a large fuel store to minimise fills

- Fully automated fuel delivery system

- High efficiency, low energy modulating main system pump

- 1 x class 2 RHI eligible ultrasonic heat meters complete with certification

- Heat Interface Unit and heat exchanger assemblies

- Full assistance with RHI application including schematic drawings

- Commissioning, programming and end user training

More details on this specific biomass boiler used on this installation can be found on the Guntamatic Powerchip page, with further details of our entire range available through the biomass boilers page.

The incentive

A project of this size would gain an approximately £22,000 every year for 20 years, index linked to inflation.