Gellifawr Hotel

Hotel group’s second biomass project replaces eight oil boilers, reduces fuel costs and secures RHI payments

Key Facts

Location

Pembrokeshire

Project included

- Guntamatic 198kW Biocom boiler system including flue system and 5,000 litre thermal store.

- Distribution pipework including internal connections to heat exchangers.

Fuel consumption

Approximately 54 tonnes of wood pellets per annum

Fuel cost saving

Wood pellets; 20%-40% vs heating oil

CO₂ saving

Approximately 55 tonnes vs heating oil

RHI payments

A project of this size would gain approximately £22,000 every year for 20 years, index linked to inflation.

Total project cost

£85,000

ROI

4-5 years (combining RHI income & fuel cost saving).

Downloads

We were looking for a renewable heating solution that would give our guests consistent and reliable heat throughout the year. Treco achieved this for us and supported us all the way, including the successful application for RHI Incentive payments.

Overview

Gellifawr Woodland Retreat is tucked away in the peaceful Gwaun Valley, a perfect woodland landscape in the Pembrokeshire National Park and a stone throw away from the beautiful Pembrokeshire coast line. The former farm and mill house retains its original charm and character and sits within 12 acres of landscaped gardens and ponds.

Seven individually decorated rooms all with en-suites, offer a modern style enhanced by beautiful views of the surroundings. In addition, the 15 cottages packed with character, charm and modern conveniences balanced with atmospheric and homely touches are the ideal base for group or family bookings.

The owners wanted to reduce both their heating costs and CO₂ emissions while maintaining the comfort of their guests.

This project was the second that this hotel group had purchased from Treco and the order was placed on the basis of the great success of the first installation.

The challenge

Treco was briefed to supply, install and commission a biomass boiler system to replace the eight oil fired boilers that were currently supplying heat and hot water.

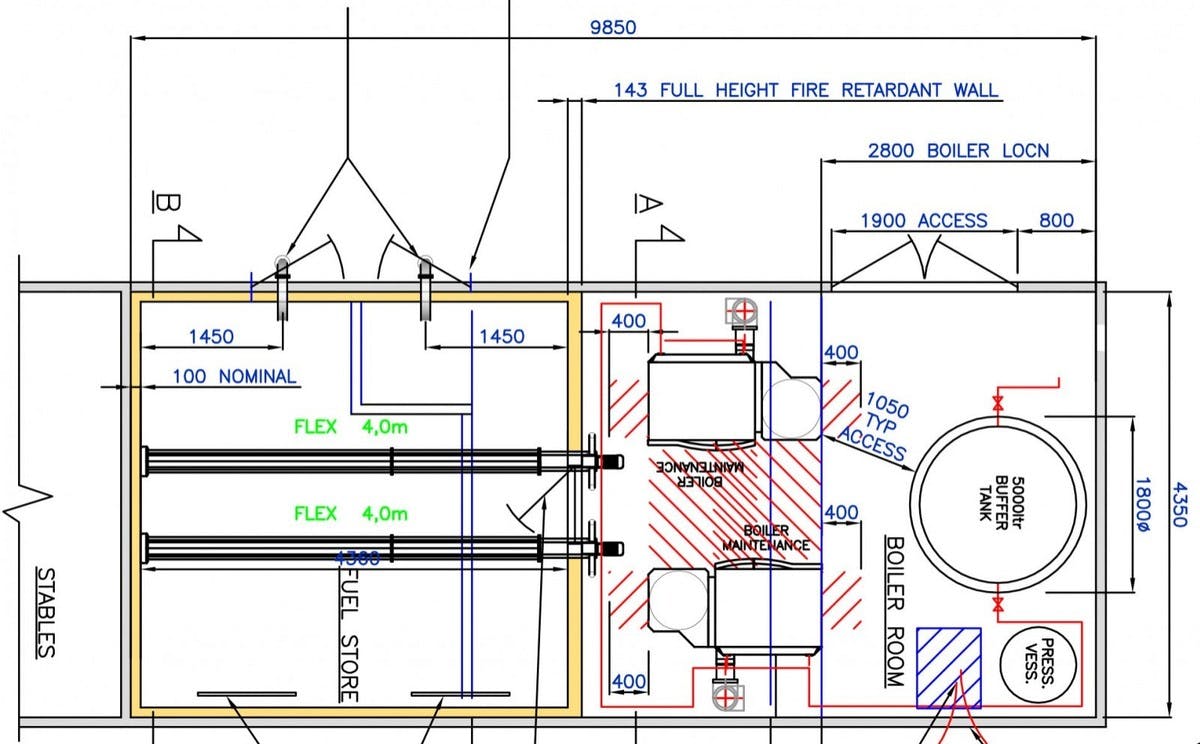

Treco designed a purpose built boiler room and fuel store with adequate access for delivery, working with the local team of plumbers and builders.

Our custom solution

Following the brief to supply, install and commission a biomass boiler system to replace the eight oil fired boilers, Treco worked with a local team of plumbers and builders, and designed a purpose built boiler room and fuel store with adequate access for delivery. It was essential that the design of the system was compliant with the Renewable Heat Incentive (RHI) requirements.

Treco installed a fully automated 198kW Guntamatic Biocom biomass boiler system, with automatic ignition. The boiler burns wood pellets which are delivered to the boiler using a suction system. A 5,000 litre thermal store was also installed on site.

The self-cleaning moving step grate system and the constant motion of the turbulators keeps the heat exchanger tubes free from efficiency-reducing deposits. The step grate not only improves efficiency, but it also allows the boiler to cope with a wide variation in fuel quality. The boiler's automatic de-ashing features and the integration of the Guntamatic Biocom biomass boiler with the existing heating system further ensured an efficient system.

A key feature of the Biocom range is market leading efficiency in modulation. This means that the boilers are able to maintain maximum 96% efficiency between 26%-100% of output. This leads to reduced fuel consumption, more heat for your money and a more complete burn.

The touch screen control panel gives the user key performance information such as combustion efficiency and boiler output. It assists with fault diagnosis, maintenance and an optional GSM module which gives you control from your smartphone. The control panel enabled the client to monitor boiler performance at all times.

In addition, Treco also provided assistance with the final RHI application including schematics.

More details on this specific biomass boiler used on this installation can be found on the Guntamatic Biocom page, with further details of our entire range available through the biomass boilers page.

Project summary

Solution snapshot

Treco‘s design, installation, commissioning and maintenance service included:

- Fully automated 198kW Guntamatic Biocom biomass boiler system, with automatic ignition.

- Burns wood pellets, delivered to the boiler by suction system.

- 5,000 litre thermal store.

- Electronic control panel, enabling the client to monitor boiler performance.

- Self-cleaning moving step grate system improves efficiency and allows the boiler to cope with a wide variation in fuel quality.

- Integration with the existing heating system and automatic de-ashing.

- Design of system compliant with RHI requirements.

- Assistance with final RHI application including schematics.

The incentive

As well as delivering fuel cost savings of 20%-40% with wood pellets versus heating oil, a project of this size would gain approximately £22,000 every year for 20 years, index linked to inflation. Together, it will see this project receive a return on investment in five to six years.