Wooden Product Manufacturer

Waste to Energy - Relocated 1MW biomass boiler

Key Facts

Location

Midlands

Project included

Kalvis 950-M1 (reused)

Duty assist 750kW gas boiler

Ceramic filter

73m3 silo

Shredder

1.4MW heat emitters

Fuel consumption

Around 2,000 tonnes per year

RHI payments

Approximately £300,000 index linked to inflation

ROI

Approximately 5 years

Annual CO₂ saving

Approximately 1,400 tonnes

The installation

Treco relocated a redundant biomass boiler from a site near Leominster to it's new home in the Midlands, where it has a new lease for life operating as a Waste to Energy system. Here waste wood produced on site is used to feed the boiler to provide heating to the 150,000 ft2 factory.

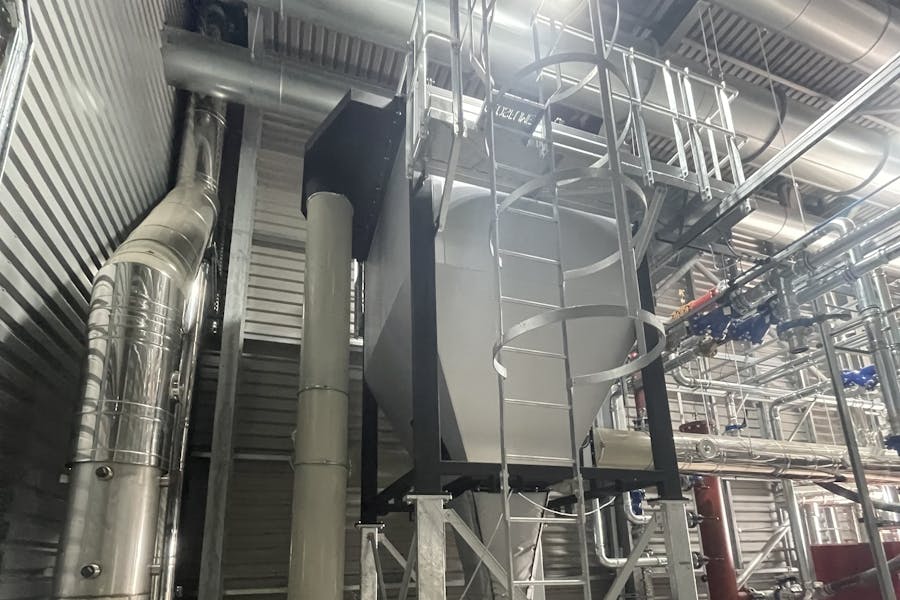

Along with the biomass boiler our scope of works included; full plantroom installation, 750kW duty assist gas boiler, downstream heating system with 1.4MW of emitters, ceramic filter to keep particulate matter emissions to the lowest possible level, a 73m3 silo to store the waste wood prior to use, and a shredder.

Through the RHI payments alone the whole project will likely be paid off in approximately 5 years, though with the fuel and disposal savings factored in it will see this period reduce.

By utilising their own waste wood its estimated that the company will save 1,400 tonnes of CO₂ per annum, helping them to progress towards achieving goals set out in their Environmental & Sustainability Policy.

More details on relocating biomass boilers can be read on our second hand biomass boiler page, with further details of our range of new systems available through the biomass boilers page.