Tipped Delivery into Bulk Store

A tipped delivery into a bulk fuel store is a popular option.

This method is best suited to sites where a lorry or trailer with a walking floor can access the site and deliver woodchip to a bulk store or clean pad outside the Plant room. It is vital the client has access to a loader or tele handler as well as the manpower available to move the fuel from a bulk fuel store into the plant room’s fuel store in batches of whatever quantity are required.

This can be a cost-effective way to manage your fuel delivery as the fuel supplier will just need to tip the fuel and will need less time on site than with other methods.

For farms, rural businesses, schools, hospitals or hotels this is a popular option as they will invariably already have the manpower and loader or tele handler already on site to manage other activities. However, if you do not have these facilities already available at your site, you will need to consider the cost of bringing in a 3rd party supplier.

We always recommend specifying as large a bulk fuel store as possible, in order to minimise the amount of fuel deliveries per year, minimise the impact on your time and to enable the benefits of the lower unit prices from bulk buying. As delivery charges will be factored in to the cost of your fuel, the fewer times the fuel truck has to visit, the cheaper your units of fuel will be.

In addition, the labour to manage this process will be significantly reduced. Also, where Planning or the layout of the proposed site limits the cost-effective construction or conversion of a large fuel store adjacent to the boiler itself, civil works can be drastically reduced.

As long as the bulk fuel store is easily accessible, dry, free from contaminants such as stones or metal and adequately ventilated, an existing outbuilding or converted shipping container can be used, keeping your total project cost under control.

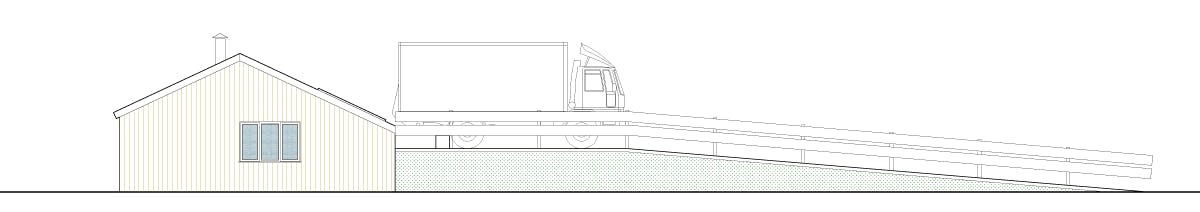

Ramped Delivery

A ramped delivery in to an underground or subterranean fuel store has obvious advantages. Your wood chip fuel supplier can use large vehicles with a simple mechanism to tip the fuel easily and quickly.

Within a fuel store that is filled via a ramp, a primary fuel pit is often utilised in conjunction with a conveying auger fitted to your Guntamatic Powerchip. This means that the fuel delivery point can also be some way from the building that the boiler will heat and allows an even distribution of wood chips within the store.

Decisions regarding the ramps themselves are best taken during the design stage of your biomass project and the costs of the ramp can be reduced by taking advantage of any natural sloping or level changes at the proposed site. In addition,

This will create a staggered effect and allow much of the weight of the fuel to be dispersed through the ramp itself, rather than pushing side loads onto the retaining walls.

The access into the fuel store’s primary fuel pit is typically a pair of metal doors across a metal grid in order to prevent the wood chips from forming lumps as they enter the store.

It is important to design the ramps so that the lorry can tip into the centre of the store.

It is advisable that structural calculations are taken, to support the lorry and fuel whilst tipping. Although this is not a service Treco offer, our design team are here to support and liaise with your structural engineer or subcontractor.

Although the initial capital outlay will be higher than the other options, this can be a cost-effective way to buy in wood chip fuel as bulk deliveries can be easily managed.

This type of fuel delivery is therefore best suited for systems of 100kW or over.

It is important to consider practicalities such as access for a large fuel vehicle through the lanes that may be near to a country business, hotel, rural school or poultry farm. There should also be adequate space for the vehicle to turn and no overhead height restrictions that may impede access to the site.

Blown Delivery

Some fuel suppliers are able to offer a blown chip service, where a vacuum tube fitted to the fuel delivery truck and a hydraulic pump feed the wood chips into the fuel store via an access hatch.

However, this option can come at a cost, particularly for smaller deliveries. You will also need to consider the distance that your site is from the fuel depot, as delivery costs will push up the unit price.

Fast Feed Auger Delivery

A further fuel delivery option is one featuring a mechanical auger and trough. The fuel tips its fuel directly inside and a fast feed auger conveys the fuel upwards then across and into the fuel store. One of the main benefits of this method is a relatively very small footprint and a smaller capital cost as there will be fewer civils required on site.

However, one drawback to this option can be that the fuel delivery vehicle might be on site for slightly longer than for your average wood chip delivery, as it will only be able to unload at the conveying rate of the auger. However, fuel suppliers which we have worked with can easily move 60m³ per hour.

Safety drives everything that we do. Please take care where fitting this type of solution within public spaces or school grounds to prevent injury the open auger section whilst it is in use. That said, the trough auger can be buried to minimise the visual impact and all fast feed systems should have a cover to prevent alien objects entering the auger.

Some of these factors can reduce the typical fuel cost saving from using wood chips of 50% versus oil, which is one of the most popular benefits of biomass heating and presumably one of your main reasons from switching to renewable heating.

Biomass fuel information

Information about the different fuel types available for biomass boilers, the regulations, considerations to take and information on procurement.

Wood chips

Wood chips are small pieces of logs or wood waste. These are formed by passing through a chipping machine, which turns them into 30mm pieces, also known as G30.

Wood pellets

Wood pellets are a type of biomass fuel, made from compacted sawdust or other waste from saw-milling and manufacturing. At 4.8kWh per kg, you only need one third of the space that you'd need for wood chips.

Logs

As a biomass fuel, logs will generally deliver 5.1kWh per kg, depending on moisture content and type of wood (hardwood or softwood, and species).

Grain

Grain can be an economical and convenient fuel for use in biomass boilers. 'Pourable' grain such as oats, wheat and barley have a low nitrogen content. Being a slightly denser fuel than miscanthus, it will require less space to store for the same amount of heat.

Miscanthus

Miscanthus, (or 'elephant grass') is a perennial grass originating from Asia. It is becoming popular as an energy crop as it can easily and quickly grow on poor quality land with no need for fertilisers or very much intervention.

About the BSL

The Biomass Suppliers List (BSL) is a list of woodfuel that has proven it meets the eligibility requirements for the Renewable Heat Incentive (RHI) scheme.