Froling TI

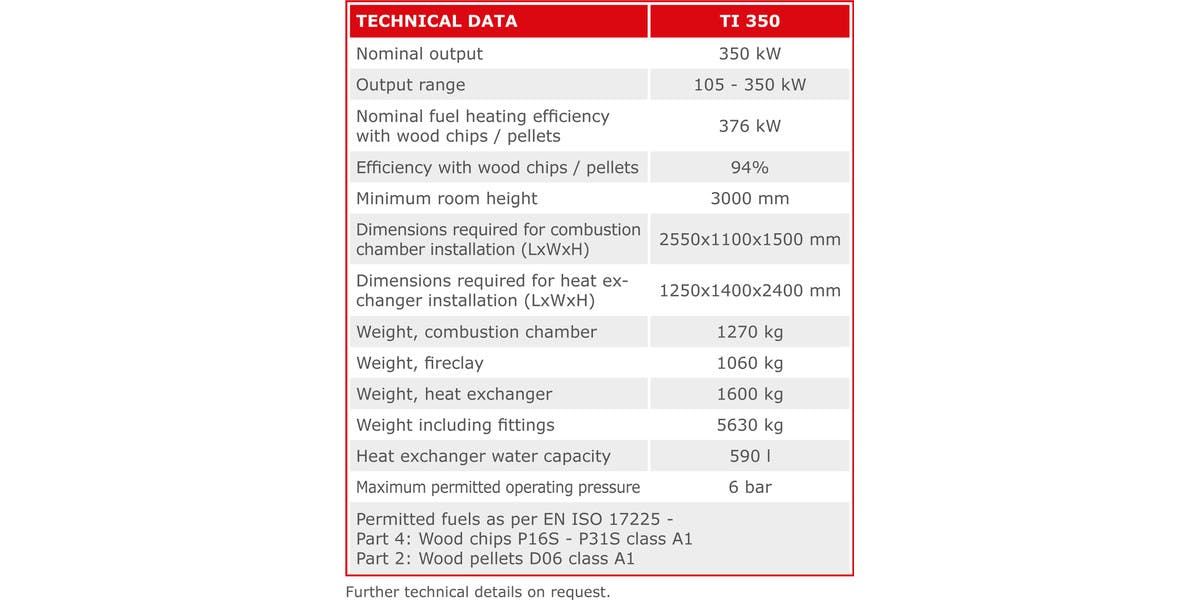

Froling's TI is a unique, fully automatic heating system for burning wood chips and pellets. It not only offers innovative combustion technology, but also a high level of convenience and operational reliability.

Fitted with industrial-grade moving grate technology, the TI's nominal output is also suitable for 24 hours' continuous operation. The H 3200 control system with touchscreen interface and full internet connectivity leaves nothing to be desired in terms of visualisation software. Lambda control, combustion chamber temperature control and flue gas re-circulation ensure that the TI meets the safety and efficiency standards associated with the Frӧling brand.

Innovative design, outstanding benefits

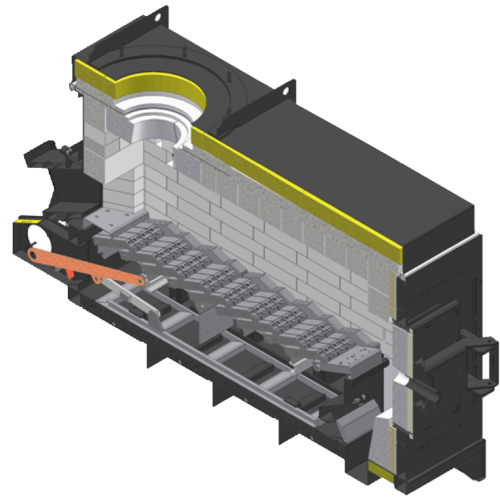

High-temperature combustion chamber

With moving grate

Benefits:

• No cinder build up

• Very low emissions

• Optimum burnout

• Automatic ash removal

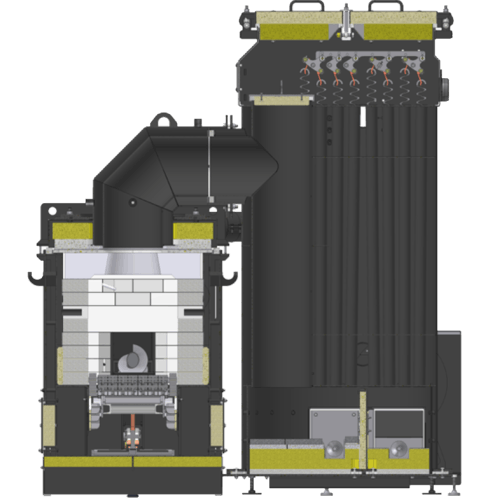

Vertical heat exchanger

Benefits:

• Optimum heat transfer

• Automatic cleaning of heating surfaces

• High efficiency

• Low dust emissions

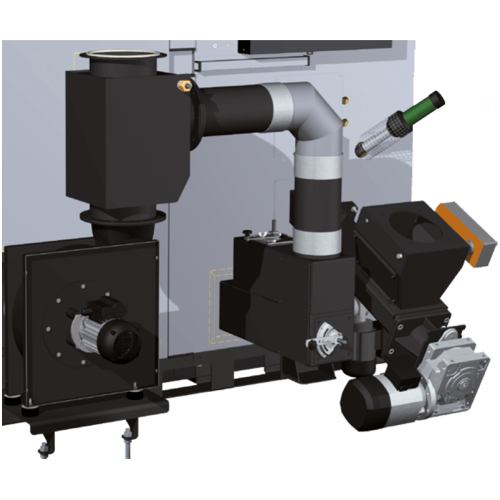

Flue gas re-circulation (FGR)

Benefits:

• Optimised combustion

• Very low emissions

Lambdatronic H 3200 control system

Benefits:

• Precision combustion control with lambda control as standard

• Large, clear control unit with graphic display

• Menu-driven operation with online help

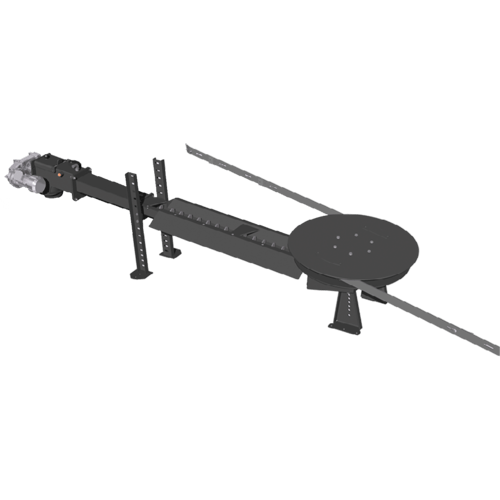

Flexible fuel transport options

Whether it's a spring blade feed system, an articulated arm or a sliding floor, the flexible feed systems from Frӧling's always ensure optimum fuel transport to the boiler. For pellets the use of an industrial suction system is also possible.

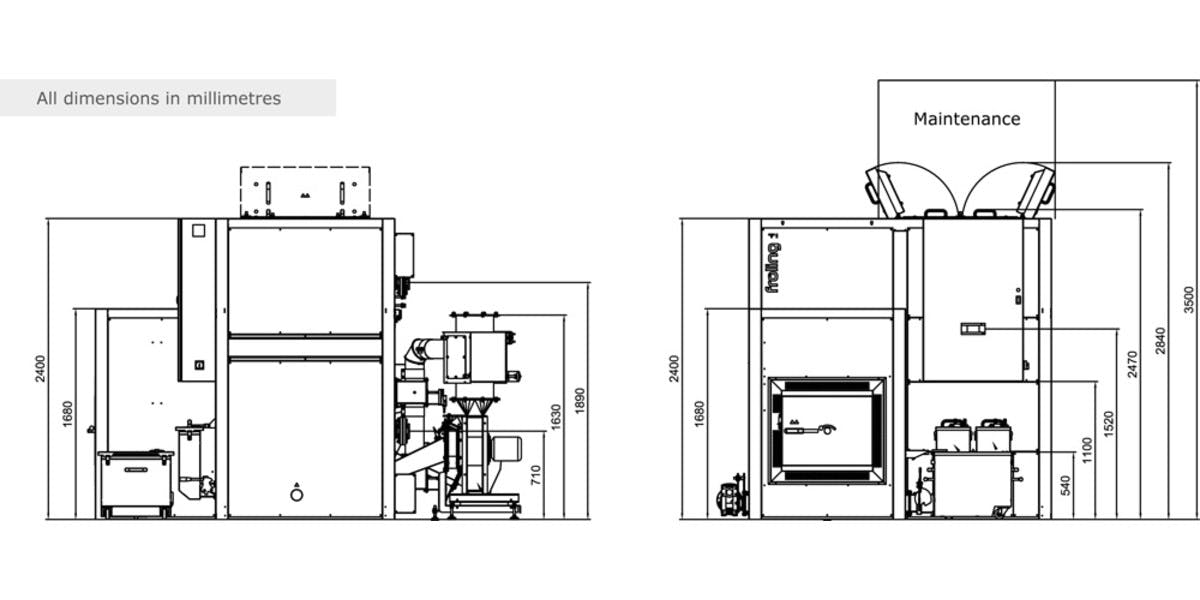

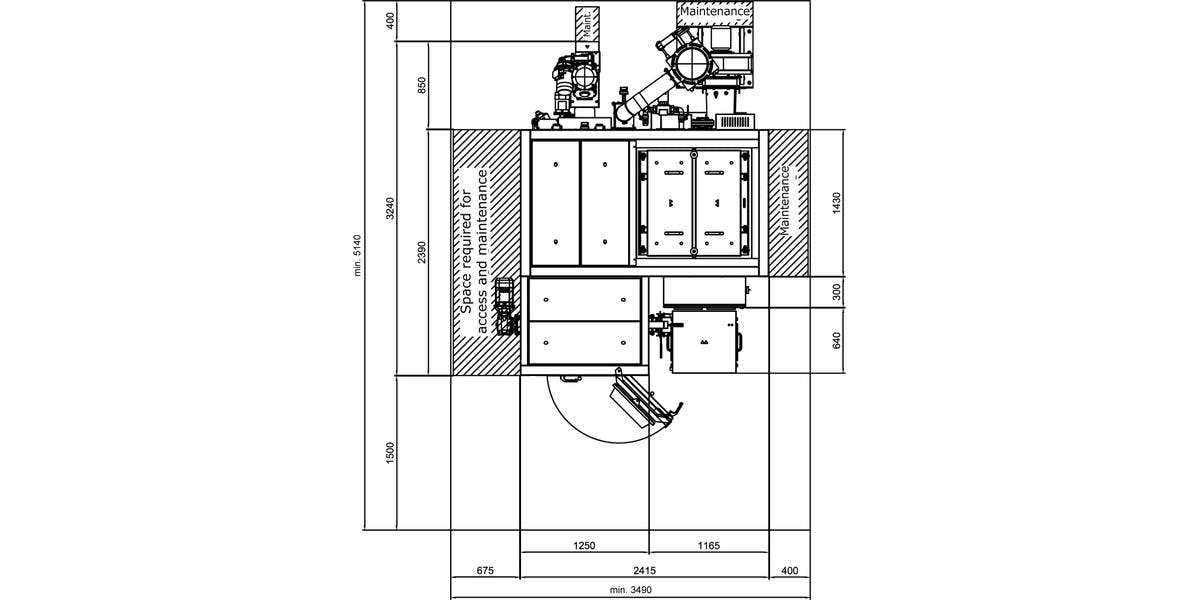

Heat exchanger

Multi-functional heat exchanger which features large heat exchanger surfaces. Convenient maintenance is ensured by large and easy to reach cleaning and maintenance openings.

Combustion chamber

Multi-layer high temperature combustion chamber for high efficiency and clean combustion.

Conveyor grate

The hydraulically operated conveyor grate with primary air intake system keeps the fuel moving continuously and ensures complete burn-out (even with heavy fuels).

Ash bin

Fully automatic ash removal.

Secondary air openings

The secondary air openings ensure optimum combustion and a complete burn-out.

Tertiary air vents

Tertiary air vents for increased efficiency during combustion. The fully controlled flue gas re-circulation AGR (optional) optimises burning (output, emissions etc.) with particularly demanding fuels.

Double tunnel vault

The double tunnel vault guarantees the optimum burn-out of fuels with a high water content.

Browse through our product range

As the importers and distributors of two of the largest Austrian biomass boiler manufacturers, there's an extensive range of systems we can offer. We pride ourselves on providing the most appropriate system for your project and will source other systems if necessary. When we need single systems above 1.5MW in size, or WID/IED boiler suitable for burning Grade C hazardous wood waste, we would look to other manufacturers such as Uniconfort. Browse through our product range or give us a call to discuss your requirements and our team will be able to hand-pick the best biomass boiler for your project.

Guntamatic Biocom

Biocom heating systems,with industrial step grate technology, combine maximum economy with minimum emissions. These biomass boilers can operate with wood pellets of varying quality.

Guntamatic Powerchip

Our Powerchip heating systems effectively combine maximum economy and minimum emissions. These boilers are perfect for burning a range of fuel types, including wood chips, pellets, grain and miscanthus.

Guntamatic PRO

The PRO series offers highly economical and future-proof heating convenience using pellets and wood chips. With an output range of up to 1MW, the PRO is suitable for a wide variety of commercial and industrial applications.

Frӧling Turbomat

Frӧling’s Turbomat is a unique heating system with a fully automatic wood burner. From wood chip and pellets to carpentry material and wet waste wood, the Turbomat will operate with a wide variety of wooden biomass material.

Frӧling TI

With the heat output of 350kW, the Frӧling TI biomass boiler's combustion chamber adapts very quickly to different performance requirements. This rapid adjustability is particularly beneficial for dry to moderately damp fuel classes.

Frӧling Lambdamat

Frӧling's Lambdamat is a unique, fully automatic heating system for burning wood chips, shavings and pellets. It not only offers innovative combustion technology, but also a high level of convenience and operational reliability.